|

|

READY

WELDER II

Weld

anywhere!

By: Tony

Carricaburu |

The

Worlds Most Portable, Affordable, Powerfull and

Versatile Mig Welder!

Introduction:

The Ready Welder II is a Completely Portable Mig

welding system with 30 to 250 amp capacity at 12 to 48

volts. With capabilities to weld steel and stainless

steel up to 3/4" thick and aluminum up to

3/4" thick. The Ready Welder II will provide you

with the power, performance and portability like no

other portable MIG welding system.

For

myself the Readywelder provides base or mobile quality

welding capabilities when ever I need them. This means

no worrying about being stranded out in the middle of

know where because of breakage. The Ready Welder II

wont just provide you with a temporary trail fix but

in some cases the Ready Welder II has been known to

provide a permanent Trail fix because of its quality

welding. The Ready Welder II can also be used at home

for custom fabrication such as custom roll cage

building. This welder shouldn't be mistaken for just a

Mobile welding system but a home unit as well. The

quality of the welds provided by the Ready Welder are

as perfect as those you would obtain from using a

traditional home unit. The Ready Welder II has an

optional gasless welding, or gas welding option as

well. For more information about the portable C02

tanks go to www.Premierpowerwelder.com

Included

in Standard ReadyWelder pak #10500:

|

-

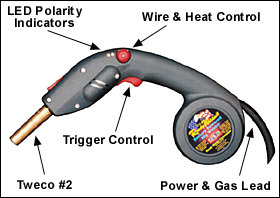

Ready Welder II MIG gun

|

|

-

One spool of steel flux cored wire

|

|

-

Ten feet of welding cable

|

|

-

Two battery clamps

|

|

-

One ground clamp

|

|

-

Extra tips and gas hose fitting

|

|

-

Heavy duty carrying case with fitted foam for

gun and accessories

|

Powered

By:

The

Ready Welder II system can be powered in several

different ways. One way is to use 1, 2, 3, or 4 12

volt deep cycle batteries depending on the material

being welded. For example one 12 volt battery works

great when sheet metal welding is needed. For thicker

steel such as 1/4" angle iron, The Ready Welder

II recommends two 12 volt deep cycle battery's. The

Ready Welder II can also be used with most traditional

welders (40 VD.C. or less). For my application I chose

to run two 12 volt batteries joined together equaling

24 volts output which allows the Ready Welder to weld

up 1/2" steel with a 200 amp draw. If I were to

ad an additional battery for a total of three 12 volt

batteries combined voltage equaling 36 volts would

allow me to weld up to 3/4" steel or aluminum at

270 amps drawn. For those of you who already have an Under hood

welding unit such as the Premier Power Welder, you too

can use the Ready Welder II in sequence with your

Power Welder. The Ready Welder II can be combined with

your already existing Premier Power Welder for the

ultimate in current control welding. Combining the

Power welder and Ready Welder II allows you to weld

either MIG, TIG, or ARC style welding of your choice.

With these types of capabilities you complete all you

welding needs....ever!

Diagram

1.1

Battery

hook up:

(Diagram 1.2)

In order to obtain 24 volts from two standard sized 12

volt battery you must perform the following

instructions. First thing is first, Be extremely careful

when working with batteries, they can easily cause

major injury. Ok, with two battery's sitting next to

each other connect Battery-1's Positive(+) to

Battery-2's Negative(-) using 4awg. wire. Be careful

not to let the connections spark or arc when

connecting. Now that you have that connected you

simple use the available Positive(+) connection and

the other battery's Negative(-) connection to hook up

to anything requiring 24 volts. See Diagram 1.2 for

details.

(Click on images for large full page view)

IMPORTANT

NOTICE:

If your vehicle is equipped with the premier power

welder and you plan on buying a readywelder to use in

conjunction with your power welder note that you

cannot weld on your own vehicle. When using the

Readywelder attached to your power welder its ok if

you weld on other vehicles besides your own or parts

off the vehicle. This has to do with a polarity issue.

When the two units are connected together they create

a straight polarity current.

FINAL

RESULTS:

EXAMPLE

1: (Rocker Panels)

I was very impressed with the overall performance of

the Ready Welder. It was just like welding with a home

unit. I welded several different types of steel to

test the welder in conjunction to the usual materials

I work with and would use the welder for. After

running a couple nice beads I felt really comfortable

with the Ready welder and infact it might replace a lot

of the use my Lincoln Home Mig welder would perform.

For

my first test we welded some custom built rocker

panels on my friends Rock Crawler XJ (Cherokee). The

construction of the Rocker panels is a combination of

1/8" and 1/4" Steel. Below are some pictures

of some fresh welds performed with the Ready welder

II. These are the 1/8" steel rocker panels.

Notice the clean smooth welds.

EXAMPLE 2: (Motor Mounts)

For the next test we gained some real confidence in

the Ready Welder II. For the next custom built project

we made some Chevy S-10 4.3L motor mounts with

polyurethane bushings. The Materials used for this

project was 1/4" steel, combination strap and

round stock. As im sure you understand this is a real

test, We were a bit hesitant about using the Ready

Welder but after testing the Rocker panels on the

Cherokee we knew what the Ready welder was capable of.

Keep in mind this isn't your average 4.3L V-6. This

4.3's been modified and is currently peaking 260hp. So

you can imagine the strength needed to hold this motor

in place.

Notice in the pictures how clean and smooth the welds

came out. We performed this on both motor mounts. The

mounts have been holding up for about 3 weeks and show

no sign of stress.

EXAMPLE

3: (Upper A-Arms)

For the final test we made some 100% custom upper

A-arms for the same S-10 pre-runner. We used 1/4"

thick round steel for this fabrication. We also use a

couple pieces of 1/4" plate for additional

support and strength. These A-Arms to a little while

to make but was pretty easy welding thanks to the

Ready Welder. I know some of you may think we put a lot

of confidence in a product but after the other test we

knew the Ready Welder was asking for a bigger

challenge.

**

UPDATE:

1-10-04

We've been using this welder for well over 3 years now

with no problems at all. It works perfect every time.

Excellent product!!

CONTACT

INFORMATION:

Premier

Power Welder P.O box 639 cadondeal colorado, 81623

1-800-541-1817 Tech fax: 970-963-8875

Website: www.Priemerpowerwelder.com

|